You want to look for a robust machine that is designed to work on a consistent basis, for long hours and without failure.In this article, we've brought together the best laser cutters on sale today. It is therefore essential that the 3D printer comes with a wide range of functional biomaterials to manufacture several types of orthoses: rigid, semi-rigid, flexibles… 3. Orthopaedic devices are made from different materials to respond to different needs. That’s why we advise you to start with an additive process that is easier to understand and control, such as the thermal extrusion technique. It may be difficult to understand how a 3D printer works, especially if you are a novice in the field. Are you ready to join them? The essential characteristics to look for when choosing a 3D printer for O&P applications 1. Medical equipment manufacturers are now more than ever investing in 3D technology to optimize the fabrication of orthoses and prostheses. If you still have some dilemmas to tackle after reading our expert guide, don’t hesitate to reach out. You can find more information on these printing techniques and even some 3D printers we recommend in our expert guide on 3D printing.

#Best 3d laser printer series

We decided to share all the knowledge we’ve gained during our R&D projects with you through a series of guides. Understanding these (dis)advantages is key in choosing a printer that suits your workshop. Over the years, we have become experts in merging the fields of orthopaedics and 3D technology and discovered each 3D printing technique's advantages and disadvantages.

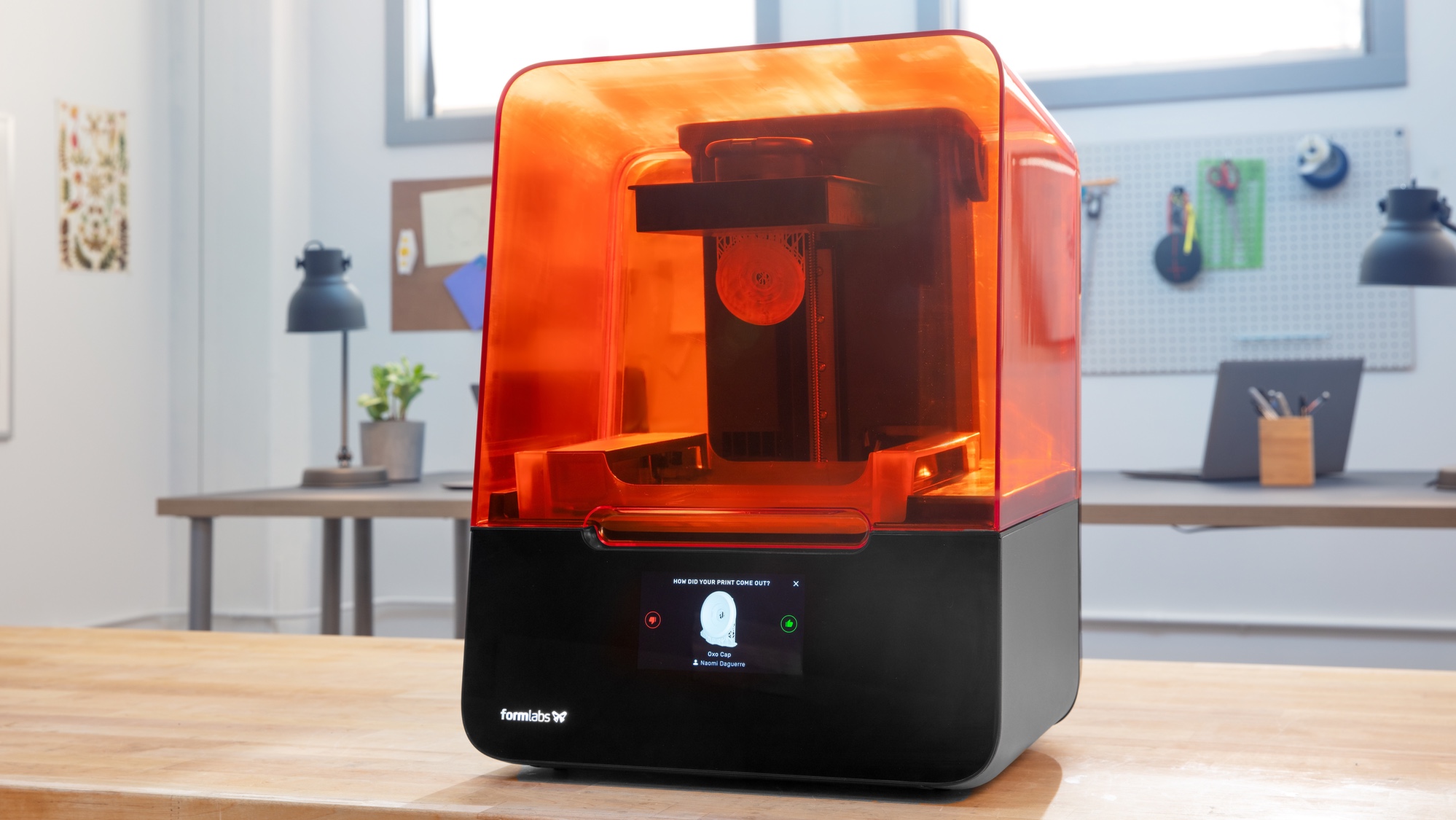

SLA was the first additive process invented: a UV laser beam solidifies a liquid resin.

Layer-by-layer the orthopaedic device is created. FDM (Fused Deposition Modelling), also known as FFF (Fused Filament Fabrication), is based on thermal extrusion: A thermoplastic filament is melted and put on the building platform.There are various 3D printing techniques available for O&P applications : Life cycle of 3D printed orthopaedic devices Reducing the need for raw materials also results in significant cost savings. The waste efficiency of 3D printing is not only an ecological benefit. Furthermore, it is possible to recycle most materials used. The waste is minimal because you load the printer with just the necessary amount of material needed to build the orthosis (and support structure). When compared to subtractive techniques like CNC machines, 3Dprinting generates much less material waste. The material waste generated by 3D printing depends on the type of additive manufacturing. When the 3D model is optimally designed, and the printer settings are tested and approved, the printing is smooth, and the orthosis doesn’t need additional adjustments to perfectly adapt to the patient’s body part. With 3D printing, it is possible to reduce the number of procedures needed for the manufacturing of orthoses, leaving a smaller window for mistakes. Additionally, parts of the process like orienting the 3D model, determining the print settings, and sending it to the proper printer can be automated as well. As such, you can print overnight to accelerate the production time. After launching the 3D printer, it can complete the entire printing process without intervention from the user. AutomationģD printing is becoming increasingly automated. With 3D printing, this is no longer the case. Building complex shapes with fewer components may not be feasible because of tool access restrictions, or because additional equipment may be required in order to remove material from a specific area.

#Best 3d laser printer manual

With manual manufacturing or milling, there are many restrictions on the orthosis geometry that can be created. The process of creating orthotics with 3D printers Why is 3D printing rapidly revolutionizing the O&P industry? 1.

0 kommentar(er)

0 kommentar(er)